MS9000GTIR Rework Station

MS9000GTIR

MS9000GTIR is the automatic heating rework system

that the closed circuit control system with the high response

middle-range infrared rays (MIR) heater and the remote temperature

sensors. The MIR heater operated at the top and the bottom. and

there heater systems are controlled by the closed circuit each.

Furthermore, the remote sensors are always checking the temperature

of the board, during heating of the system. Therefore, the machine

can be reworking without the temperature profile data.

-

The temperature of the board and the package is always

managed, during the reworking.

-

It is not necessary to create the temperature profile

data.

-

The nozzle change is un-necessary.

-

Automatically pickup of the component.

-

Automatically replace of the component.

-

It can manage the heating of the under the board.

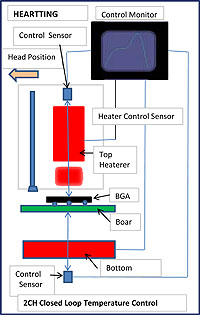

Operation Diagram

Heater Control diagram / Mounting diagram

Direct mode:

MS9000GTIR is a auto-reworking system which can be rewirking, always

managing temperature by closed circuit control system. It was realizable

with the original heating head which it moves horizontally of the

heating head and vacuum head are changed. The temperature sensor for the

board has two managing locations. They are the surface of the

reverse-side of the board, and other one is the surface of the package.

Those sensor always detects of temperature with perpendicularly. When it

supply a component and or remove, the head for heating is moves

horizontally, and automatically changed to the head for vacuum. In this

case, It is called direct mode. MS9000GTIR has other two kinds of

control mode, It is a AP mode, and M mode.

AP mode:

It can be create automatically of a optimal

temperature profile data by ATTS function. ATTS system is Automatic

Thermal Traces System, it had already operated at MS9000SAN rework

system.

M mode:

It is for manual setup of the heating data, It has 6

heating zones, and heating data input to each by manually.

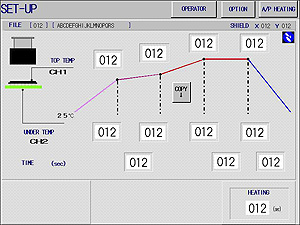

Direct Mode Operation

Touched Panel Screen

Direct mode is controlled by closed circuit

system. The required temperature profile data is input to the four

windows, MS9000GTIR is operated automatically as the setup temperature

data. Four windows of the upper side are the temperature for solder. and

the under side windows are for reverse-side temperature of the board.

The time data will be automatically input by the machine. The all input

data can be change always by manually. MS9000GTIR automatically hearts

according to input data.

AP Mode is

controlled by ITTS function.

This is use when it cannot control with the remote

sensor precisely. such as the case of the surface of the package has

reflects, like a mirror. and when the surface of the package is

complicated and is not flat, such as a connector. In those examples, the

remote-sensor may not operate precisely.

In AP mode, the surface of the package and the

reverse of the board are required with the sensor, and temperature

controlled them. After that, the system is reproduces the same heating

profile faithfully without sensors.

M Mode is

use when the load capacity of heat is too

large and or the sensor cannot be wearing correctly to the component.

MS9000GTR has 6 zones of data windows, the suitable temperature control

data for each is put in and tested.

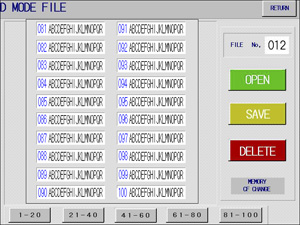

Data File

Data File Screen

The setup data can be saved at each mode. D mode data

is maximum of 100 files, AP mode data is maximum of 100 files, and M

mode is maximum of 50 files.

the data is managed by the Windows Excel CSV files.

The data can be send to the PC, by the CF memory-card. The data can be

analyse with the original software with the Excel on the PC.

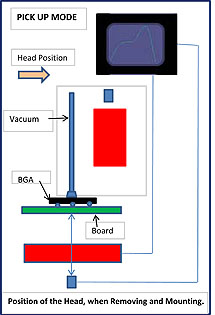

Auto-Parts Supply

Parts Pickup and Replace

Z axis of MS9000GTIR is by auto-servo controlled. The component can be

pickup automatically from the parts supply stage of MS9000GTIR. And the

picked up component is mounted to the board automatically.

Adjustment of the Heating Range

Heart Range Adjustor

The heart range of the top heater can be adjust by

the shutter system of the head. The shutter is adjustable each in Y and

X direction. They are possible to change by 10mm to 50mm each.

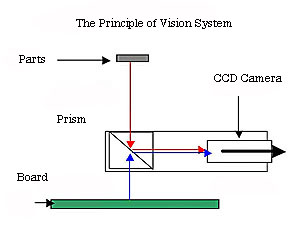

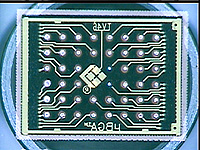

Vision System

Optical image equality System

The positioning system is by optical image equality.

It is the system that it displays the land image of the board and the

pattern image of the part on the monitor at equal magnification. If

those images fit, it will be the completion of positioning. The sample

below images are 6x8mm CSP.

Parts image+board image+both of images.

Both of image + adjust = Completion

positioning.

Wide Bottom Heater System (Option)

Optional Wide Bottom Heater

The optional wide bottom heater system is very

effective to the large size board. And, it may be able to escaped from

warped the board by heating.

Specifications

| Item |

Specification |

| Component size |

3.0 x 3.0 ---50

x 50mm |

| Board Size |

50 x 50 ---400

x 500mm max |

| Fine Adjust for Rotation |

±5 degrees max

by Z axis by manual |

| Fine Adjuster X and Y |

±5.0mm max by

XY Table by manual |

| Board Thickness |

3.5mm /3Kg Max

|

| Clearance of under the

Board |

25mm Max |

| Clearance of the board Top |

45mm Max |

| Z Axis |

servo control |

| Under support for the board |

by 4 pins on 2

railes |

| Heater Control

System(PID) |

Direct |

Closed Loop

with remote-sensor x 2 |

| AP |

ITTS Auto-Profile x 2 |

| M |

Manual 6 zones |

| Parts Pick Up |

Auto-Pickup by

Vacuum Bit. |

| Parts replace |

Auto-Replace by

servo controlled Z axis. |

| Controller |

Touched Panel

10.4inch Color with Logic controller |

| Top heater |

800VA Middle IR |

| Area

Range:10x10 -- 50x50mm by XY Shutter |

| Bottom Heater |

800VA Middle IR |

| Wide Bottom Heater |

1KVA x 2 Far-IR

(Option) |

| Control Data

Save |

Direct mode:100

files max |

| AP mode: 100

files max |

| M mode: 50

files max |

| Control Data Memory |

Excel CSV file

in the CF memory |

| Temperature Measuring |

CA-K:

2(controller)+2CH(measuring)

|

| Data Analyzer |

Peak Temp x 4 /

Time-Interval x 2 x 4 |

| Data Graph |

4CH max |

| Monitor |

640x480 dot

10.4 inch (Ext by RGB) |

| Vision System |

AF 70x max with

splitter system |

| Power |

200--240V 2.0

KVA |

| Dimension |

730W x 830D x

780Hmm 80Kg approx. |

| Air |

0.5Mpa Dry

|

The specification are subject to change without notice.