|

MR2533A 탁상형 리플로우 시스템

MR2533A

탁상형 리플로우 시스템

MR2533A

Table Top Type Reflow System

MR2533A는

매우

안정적인

온도

프로파일을

빠르게

얻을

수

있는

탁상형

리프로우

입니다.

ITTS(지능형

온도

추적

시스템)온도

제어

시스템은

당사의

주력

제품인

리웍

시스템에

적용중입니다.

ITTS는

리웍

시스템을

고효율로

만들었을

뿐만

아니라

쉽게

사용할

수

있게

했습니다.

이것은

리플로우

오븐에

역시

완벽하게

적용할

수

있습니다.

MR2533A is the table top type reflow which can get the very stable room

temperature with quickly. Temperature control system ITTS(Intelligence Thermal

Trace System) is used with the rework system of our main products. ITTS made

rework system highly efficient, and moreover made it easy-to-use. It was

completely applied also for reflow oven.

특징

FEATURE

l

ITTS에

의한

최적

온도

프로

파일을

손쉽게

작성

Easy create of the optimal temperature profile by ITTS.

l

터치

패널

제어기에

의한

쉬운

운영

Easy operation by touch-panel controller.

l

탁상형으로

설치

공간의

최소화

Installation is possible at a small place by table top type.

l

고효율

히터에

의해

준비시간이

매우

짧음

Ready time is very shortly with highly efficient heater.

l

룸

온도는

5도

이하로

매우

안정적

The

stability of room temperature is less than 5 degrees.

운영

OPERATION

MR2533A는

유니버셜

보드

홀더가

있고

스프링에

의해

보드를

고정합니다.

게다가

보드

홀더는

장비의

서랍에서

탈부착

할

수

있습니다.

모든

가열

조건의

설정,

셋업

또는

운영은

터치

패널에서

합니다.

그러므로

운영은

매우

쉽고

정확하게

할

수

있습니다.

MR2533A는

N2 가스를

사용할

수

있어

N2 분위기

구현이

가능합니다.

몸체는

상하부

2개로

나누어진

구조로서

유지보수가

용이합니다.

MR2533A

has universal type board holder, and it fixes a board by spring. Furthermore,

the board holder can be detached and attached from the drawer of the machine.

All of creation of heating conditions, a setup, or operation are from the touch

panel. Therefore, operation is very easy and can be correctly. MR2533A has an

input for N2 gas. Therefore, it is possible to use by N2gas. The body is the

structure where it is divided into two up and down, it is for easy maintenance.

손쉬운

유지보수

For easy maintenance

컨트롤러

Controller

First Screen ....../.........Key board on the screen

MR2533A의

제어는

긴급정지와

전원공급

스위치를

제외하고

터치패널

모니터에서

합니다.

모든

데이터

스텝과

장치의

운영은

터치패널에서

합니다.

키보드는

필요시

화면에

나타납니다.

Control of

MR2533A is on the monitor panel except of the switch for emergency stop and

power source.. and the monitor is a touch panel. All of a setup of data and the

operation of the machine are from the touch panel. The key board will be appears

on the screen when it is required.

배기

Exhaust

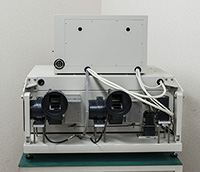

뒷면

사진Back

image

MR2533A는

2군데

배기구가

있습니다.

이것들은

오븐을

빠르게

냉각시킵니다.

게다가

N2 가스

공급용

입구과

N2 가스

검출용

출구가

있습니다.

레버로

각각

열거나

닫을

수

있습니다.

MR2533A has 2 of Exhaust, they will be cooling in

the oven quickly. Furthermore, There is a input for supplying of N2 gas. And

also output for testing of N2 gas. Each can open and close with a lever.

보드

고정대

Board Holder

장치에는

보드

고정대가

있고

이

홀더는

쉽게

제거할

수

있습니다.

홀더는

조정

가능한

것으로

보드를

고정할

수

있습니다.

게다가

하부

지지

핀

시스템이

첨부되어

있습니다.

홀더를

분리할

수

있으므로

지지핀의

위치를

쉽고

정확하게

맞출

수

있습니다.

There is a board holder in the machine, and the

holder can be desorb easily. The holder can hold a board by adjustable one.

Furthermore, the under support pin system is attached. Since the holder is

separable, a position of a support pin is easy and, moreover, exact.

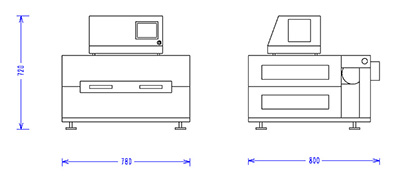

외형

치수Dimension

사양

Specifications

|

항목

Item |

사양

Specification |

|

보드

크기

Board Size |

50x50mm min.~

250 x 330mm max. |

|

보드

두께 및

무게

Board Thickness & Weight |

0.5mm min.~

3.5mm max. 3.0Kg max. |

|

보드

설치

Board Installation |

Universual

Board Holder |

|

상하부

보드 공간

Top & Bottom of the board Space |

20mm max.

(each) |

|

가열

방법

Heating Method |

Extreme Infared

Radiation |

|

냉각

방법

Cooling Methed |

125Фmm Two

Exhaust |

|

상부

히터

Upper Heater |

IR 1800VA

(300VA x 6) |

|

하부

히터

Lower Heater |

IR 1800VA

(300VA x 6) |

|

온도

제어기

Temperature Controller |

Automatic

Thermal Profile Control System (ITTS) |

|

운영

Operation |

By Touch Panel |

|

프로파일

데이터

Profile Data File |

80 files (40

files for ITTS / 40 files for Manual) |

|

측정

온도

Measuring Temp |

2CH for ITTS

control |

|

온도

정확도

Temp Accuracy |

Less than ±5℃ |

|

전원공급

Power Supply |

200~240V 4.1KVA

2P |

|

외형

치수

Outer Dimension |

780W x 750D x

720Hmm 90Kg approx. |

|

N2가스(사용시)

N2 gas (If used) |

0.3Mpa or more |

본

사양서는

예고없이

변경될

수

있습니다.

The

specification are subject to change without notice.

|