|

JTE 시리즈

JTE

시리즈

특징Feature

:

①

Totally meet various requirements for lead free processing.

②

Standard 8 couples of up and down zones with patented air management

system to make hot air convection more efficient and faster thermal

compensation.

③

PLC+PID closed loop control to achieve high precise temperature control

and repeatable profiles.

④

Dual temperature sensors and dual safety control system shall cut off the

power while abnormal case occurred.

⑤

The various alarm function: Over temperature alarm, abnormal speed alarm

and Board dropped alarm.

Parameters:

|

Model |

JTE-800 |

|

Dimension |

5310X1353X1490 |

|

No. of Heating Zone |

Top/Bottom 8 |

|

Length of heating zone |

3121mm |

|

No. of cooling zone |

上2 |

|

Air exhaust requirement |

10m³/minx2 |

|

Warming time |

About.30 minute |

|

Temperature control accuracy |

±1.0℃ |

|

Temperature deviation on PCB |

±1.5℃ |

|

PCB Max. width |

400mm |

|

Component Height |

PCB Top/Bottom25mm |

|

Conveyor direction |

L→R (Option:R→L) |

|

Conveyor type |

Chain+ Mesh |

|

Conveyor speed |

300~2000mm/min |

|

Cooling type |

Forced air cooling |

The

actual machine should be prevail if parameters changed.

JTR

시리즈

Feature:

①

Longer heating area makes higher production efficiency and throughput.

②

15% improvement of heat transfer efficient resolved more complicated and

larger PCB lead-free technology.

③

Strengthened main sweep keep rail no transverse deformation, no board

stuck and dropped.

④

Chamber designed for fully protecting and closing to keep no leaving of

N2, the lowest content of O2 can be 150ppm.

⑤

Low consumption of N2, 20-22 m³/H of N2 reflow in O2 content is

300-800PPM condition.

Parameters:

|

MODEL |

JTR-600/JTR-600-N |

JTR-800/JTR-800-N |

JTR-1000/JTR-1000-N |

JTR-1200/JTR-1200-N |

|

Outside Dimension(L*W*H) |

4190 x1430 x1530 |

5520 x1430 x1530 |

6300 x 1430 x 1530 |

7050 x 1430 x 1530 |

|

Weight |

1850KG |

2400KG / 2500KG |

2700KG / 2800KG |

3000KG / 3100KG |

|

Number Of Heating Zones |

Up /Bottom 6 |

Up /Bottom 8 |

Up /Bottom 10 |

Up /Bottom 12 |

|

Length Of Heating Zones |

2295mm |

3110mm |

3890mm |

4640mm |

|

Number Of Cooling Zones |

1(Cool Air Conversion) |

Up 3 / Bottom 3 (Cool Air Conversion) |

|

Exhaust Volume |

10 M3 / min x 2 ( Exhausts) |

|

Electric Supply Required |

3 phase, 380V 50/60Hz (Optional: 3 phase, 220V 50/60Hz ) |

|

Electric Power Required |

48KW / 51KW |

64KW / 67KW |

80KW / 83KW |

93KW / 97KW |

|

Power For Warm Up |

24KW / 26KW |

30KW / 32KW |

36KW / 38KW |

40KW / 42KW |

|

Power Consumption |

6.5KW / 7KW |

9KW / 10KW |

10KW / 11KW |

11KW / 12KW |

|

Warming Time |

Approx. 20 minu |

Approx.25 minu |

|

MODEL |

JTR-800D/JTR-800D-N |

JTR-1000/JTR-1000-N |

JTR-1200/JTR-1200-N |

|

Outside Dimension(L*W*H) |

5520 x 1660 x 1530 |

6300 x 1660 x 1530 |

7050 x 1660 x 1530 |

|

Weight |

2750KG / 2850KG |

3050KG / 3150KG |

3350KG / 3450KG |

|

Number Of Heating Zones |

Up / Bottom 8 |

Up / Bottom 10 |

Up / Bottom 12 |

|

Length Of Heating Zones |

3110mm |

3890mm |

4640mm |

|

Number Of Cooling Zones |

Up 3 / Bottom 3 (Cool Air Conversion ) |

|

Exhaust Volume |

10 M3 / min x 2 (Exhausts) |

|

Electric Supply Required |

3phase, 380V 50/60Hz (Optional: 3 phase, 220V 50/60Hz ) |

|

Electric Power Required |

64KW / 67KW |

80KW / 83KW |

101KW / 105KW |

|

Power For Warm Up |

32KW / 34KW |

38KW / 40KW |

42KW / 44KW |

|

Power Consumption |

10KW / 11KW |

11KW / 12KW |

12KW / 13KW |

|

Warming Time |

Approx. 30 min |

| |

|

|

|

|

|

|

The

actual machine should be prevail if parameters changed.

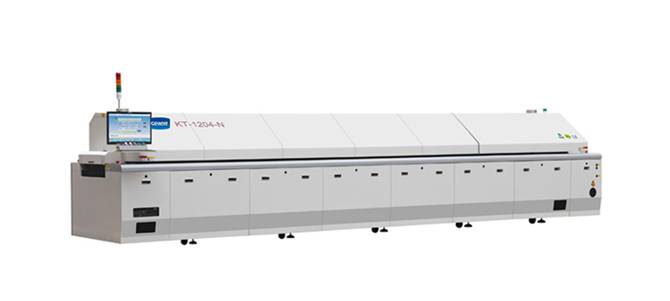

KT

시리즈

KT

Series

Features:

①

High speed, high efficiency, conveyor speed can run 160cm/min. in normal

soldering process.

②

Prevent deformation design as well as two-phase rail composition.

③

New two level flux reclaim system with multi-zones collecting.

④

Whole tunnel nitrogen protection and oxygen concentration monitoring, the

02 ppm can be checked automatically or manually.

⑤

New enhanced 4 cooling zones which are able to cool down the PCBA to 50℃

even in large volume lead free process.

Parameters:

|

Model |

KTD-0804/KTD-0804-N |

KTD-1004/KTD-1004-N |

KTD-1204/KTD-1204-N |

|

GENERAL |

|

|

Outside Dimension |

5900X1725X1630mm |

6622X1725X1630mm |

7313X1725X1630mm |

|

Standard Color |

Computer Grey |

Computer Grey |

Computer Grey |

|

Weight |

Approx.3150KG/3300KG |

Approx.3650KG/3800KG |

Approx.4150KG/4300KG |

|

Electric Supply Required |

3 Phase,380V 50/60HZ(Optional:3 Phase,220V 50/60HZ) |

|

Electric Power |

71KW/74KW |

89KW/92KW |

101KW/105KW |

|

Power For Warm Up |

33KW/35KW |

35KW/37KW |

40KW/42KW |

|

Power Consumption |

9KW/9.5KW |

10KW/11KW |

11.5KW/13KW |

|

Components Clearance |

PCB Top:30mm Bottom:25mm |

|

Model |

KTS-0804/KTS-0804-N |

KTS-1004/KTS-1004-N |

KTS-1204/KTS-1204-N |

|

GENERAL |

|

|

Outside Dimension |

5900X1495X1630mm |

6622X1495X1630mm |

7313X1495X1630mm |

|

Standard Color |

Computer Grey |

Computer Grey |

Computer Grey |

|

Weight |

Approx.2800KG/2950KG |

Approx.3250KG/3400KG |

Approx.3700KG/3850KG |

|

Electric Supply Required |

3 Phase,380V 50/60HZ(Optional:3 Phase,220V 50/60HZ)

|

|

Electrical Power |

65KW/69KW |

81KW/85KW |

93KW/97KW |

|

Power For Warm Up |

30KW/32KW |

32KW/34KW |

37KW/39KW |

|

Power Consumption |

7.5KW/8.5KW |

8.5KW/9.5KW |

10.5KW/11.5KW |

|

Components Clearance |

PCB Top:30mm Bottom:25mm |

|

Model |

KTS-0804L/KTS-0804L-N |

KTS-1004L/KTS-1004L-N |

KTS-1204L/KTS-1204L-N |

|

GENERAL |

|

|

Outside Dimension |

5900X1725X1630mm |

6622X1725X1630mm |

7313X1725X1630mm |

|

Standard Color |

Computer Grey |

Computer Grey |

Computer Grey |

|

Weight |

Approx.3100KG/3250KG |

Approx.3600KG/3750KG |

Approx.4100KG/4250KG |

|

Electric Supply Required |

3 Phase,380V Phase,220V 50/60H (Optional:3 50/60HZ) |

|

Electric Power |

71KW/74KW |

89KW/92KW |

101KW/105KW |

|

Power For Warm Up |

32KW/34KW |

34KW/36KW |

39KW/41KW |

|

Power Consumption |

8KW/9KW |

9.5KW/10KW |

11KW/12KW |

|

Components Clearance |

PCB Top:30mm Bottom:25mm |

The

actual machine should be prevail if parameters changed.

RS

시리즈

RS

Series

Features:

①

Independent Air Velocity Controlling by section can achieve flexible

processing adjustment, therefore dealing with various & complicated Lead Free

Processing easily.

②

New Cooling Configuration to make the filtered or reclaimed air back to

oven chamber, it reduced the thermal loss as well as get better flux

reclamation.

③

New Air Management System with significant energy save, lower electric

power consumption & lower carbon.

④

The chambers with multi-layers and thicker thermal insulation to get

lower temp of oven surface

Parameters:

|

Model |

RS-800/RS-800-N |

RS-1000/RS-1000-N |

|

Dimension(L*W*H) |

5378X1320X1490 |

6605x1320x1490 |

|

No. of Heating Zone |

Top /Bottom 8 |

Top /Bottom 10 |

|

Length of heating zone |

3110mm |

3892mm |

|

No. of cooling zone |

Top2 |

|

Air exhaust requirement |

10M3/minx2 |

|

Warming time |

About.30 minutes |

About.35 minutes |

|

Temperature control accuracy |

±1.0℃ |

|

Temperature deviation on PCB |

±1.5℃(by

JT Board Test Standard) |

|

PCB Max. width |

400mm (Option:610mm) |

|

Rail width range |

50~400mm(Option0~400mm) |

|

Component Height |

PCB Top/Bottom25mm |

|

Conveyor direction |

L→R (Option:R→L) |

|

Conveyor speed |

300~2000mm/min |

|

Cooling type |

Air: enhanced air cooling; N2 reflow oven reflow oven: Cooling

machine’;lh9l-0 |

| |

|

|

|

The

actual machine should be prevail if parameters changed.

|